V-belts

V-belts

V-belt is a collective term for trapezoidal drive belts that non-positively transmit torques in mechanical drive systems. They can be encased or raw edged. High-quality materials, careful production processes and the correct choice of product ensure maximum operational reliability. The profile, length, and material of the V-belt and the construction and material of the tension members will vary, depending on the application and specific requirements.

Further information about our V-belts:

V-belts are either encased or raw-edged. Essentially, they differ in their profiles, in other words their height-to-width ratio, then in the materials used and in the construction and material of the tension members. Normal standard versions are oil-resistant under certain conditions and heat-resistant up to approx. 70 °C ambient temperature. Special versions (with minimum purchase quantities) are also available, of course:

- electrically conductive V-belts with approval certificate

- extra heat-resistant V-belts, ambient temperature 70 °C - 100 °C

- extra oil-resistant V-belts

- extra cold-resistant V-belts

- selected smooth-running V-belts

In multi-groove pulleys, the use of set-constant belts is mandatory, which should be re-tensioned after a short running time. It is worth checking the pre-tensioning using a frequency meter, a tensiometer or a Krikit tension gauge.

Today's drive systems place high demands on V-belts. Until the late 18th century, the simplest transmission elements such as ropes or flat belts were made of chrome leather. The industrial revolution, the invention of mastication and the vulcanisation of rubber (in the first half of the 19th century), development of the first electric generator - all these achievements made possible an improvement in the quality of the original flat belts and established further applications in drive technology. Continuous improvements eventually led to the invention of the first V-belt, which was patented by John Gates in 1917.

The development of modern V-belts has to take into consideration the stringent requirements of a wide range of drive systems. Ever greater power transmission, longer service life even in the harshest of environments and in ever narrower spatial conditions, greater smoothness, a low price - meanwhile there is a drive belt for almost every requirement.

Of fundamental importance for the operating characteristics of the various belts are the producers' manufacturing processes and manufacturing technologies. We are the Swiss representatives for ContiTech Antriebssysteme GmbH (www.contitech.de), SWR Europe-van Dinther GmbH (www.swr-europe.de) and Bando Europe GmbH (www.bando.de). We also work with several European and Asian suppliers, who supply us with some well-known branded products.

Traditional encased V-belts

to DIN 2215

- profile 5/3 | 6/4 | 8/5 | Z 10/6 | A 13/8 | B 17/11 | 20/12.5 | C 22/14 | 25/16 | D 32/19 | E 40/25

This V-belt is the most well-known of the drive belts. It consists of a rubber core with an embedded polyester tension member, a rubber top layer and an abrasion-resistant fabric casing (except V-belt Bando VC 6/4 = PU). It is mainly used in industry, in mechanical engineering, washing machines, pumps, presses, etc.

Traditional raw-edged, cogged V-belts

to DIN 2215

- profile ZX/X10 | AX/X13 | BX/X17 | CX/X22

characteristics:

- uniform fit in the pulley grooves = smooth running

- high flexibility

- increased abrasion resistance

- extreme transverse rigidity

- not susceptible to slippage

- low elongation

- higher dynamic and more efficient power transmission

Raw-edged, cogged, high performance narrow V-belts

Select a product group:

to DIN 7753/1

- profile XPZ 9,5/8 | XPA 12,5/10 | XPB 16/13,5 | XPC 22/18

to ISO R 460

- profile 3VX 9,5/8 | 5VX 16/13,5

characteristics:

- uniform fit in the pulley grooves = smooth running

- high flexibility

- increased abrasion resistance

- extreme transverse rigidity

- not susceptible to slippage

- low elongation

- higher dynamic and more efficient power transmission

Wide angle V-belts 60° - polyurethane

- profile 3M | 5M | 7M | 11M

Made of polyurethane for high-speed drives with belt speeds up to 60 m/s. Polished edges and the enlarged flank angle of 60° provide an extremely low-vibration running behaviour. Small pulley diameters and higher belt speeds enable the construction of more compact and lightweight drives - including horizontal drives. These belts are also available as composite wide angle belts (without profile 3M). Outer lengths depending on profile from 180 mm to 2300 mm.

Reverse idler belts, black

Select a product group:

- profile 3L (3/8") | 4L (1/2") | 5L (5/8") | BANDO SA (13/7) | BANDO SB (17/9) | OLC / SC

Specially developed V-belts with an aramid tension member and black rubberised casing for applications with high impact loads or with reverse idlers.

Vehicle V-belts

maintenance-free, raw edged, cogged

- profile AVX10 | AVX13 | 11.0 | 11.2 | 11.3 | 11.5 | 11.9 |

2/AVX 10 | 2/AV 12.5 | 2/AVX 13

The quality of our best-selling vehicle V-belts from the German company ContiTech is also preferred by car manufacturers for their original equipment.

Wide V-belts / Variator belts

Select a product group:

to DIN 7719 / ISO 1604 raw edged, cogged, with following profiles:

- 13/5 | 13/6 | 20/10 | 21/6 | 22/8 | 22/11 | 23/10 | 24/10 | 28/8 | 30/10 | 32/10 | 36/13 | 37/10 | 40/13 | 41/13 | 47/13 | 50/11 | 50/13 | 51/16 | 52/16 | 55/16 | 62/22 | 70/18 | 70/22 | 75/18 | 16W | 20W | 25W | 31,5W | 40W | 50W | 63W | 80W | 100W

or to USA-Standard RMA/MPTA raw edged, cogged, in profiles with the designation e.g. 1422 V 235 (while stocks last).

characteristics:

- high power transmission

- flexibility in running direction

- smooth running

- high transverse rigidity

- resistant to abrasion and slip

- long service life

Double V-belts

Select a product group:

- profile AA/HAA 13x10 | BB/HBB 17x13 | CC/HCC 22x17

The tension member is arranged at the centre of the profile, making the double V-belts extremely flexible and low-stretch. As the tension member is rarely subjected to pressure loads because of the special shape of the double V-belt, compared with normal V-belts, this belt is ideal for serpentine arrangements.

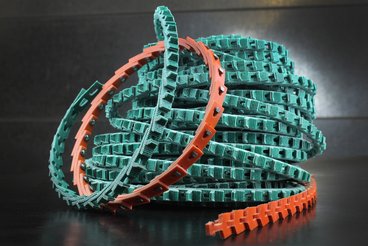

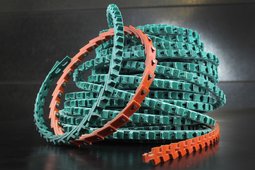

Link V-belts - polyurethane

Select a product group:

- NuTLink® sold by the metre in profiles Z 10/6 | A 13/8 | B 17/11 | 20/12.5 | C 22/14 | 25/16

- SuperTLink® sold by the metre in profiles SPA | SPB | SPC

- TabLink® sold by the metre in profiles Z 10/6 | A 13/8 | B 17/11 | 20/12.5 | C 22/14

- PowerTwistplus® double V-belts sold by the metre in profiles AA | BB | CC

Open perforated V-belts - sold by the meter

Select a product group:

to DIN 2216

- profile Y/6 (6/4) | 8/5 | Z/10 (10/6) | A/13 (13/8) | B/17 (17/11) | C/22 (22/14) | D/32 (32/20)

You can also order the corresponding V-belt locks from us for these belts, either plate connectors or joint connectors.

V-belts for the conveying section of cableways

Select a product group:

supplied in profiles XPB, XPC and 5VX, on request!

Flat belts

Select a product group:

- type 150

We not only stock flat belts by the meter up to a width of 100 mm that we can weld to the desired length, we also produce continuous lengths that we can cut from the sleeve (type 150) to your desired width.

Drive belt tensioning pulleys

Select a product group:

- profile SPZ | SPA | SPB

made from aluminium, single- and double-groove

Tensioning rollers / Idler pulleys

Select a product group:

- type B/E2 with cam, smooth contact surface → steel axle, aluminium sheaves and flanged wheels

- type B/F2 with hub, smooth contact surface → steel axle, aluminium sheaves and flanged wheels

- type B/E0 with cam, toothed contact surface → steel axle, aluminium sheaves

- type M heavy-duty series with cam

- type BSR light series without cam → for light-duty belt drives

- type RP1/RE2 to RP6/RE7 plastic tensioning pulleys