Timing belt pulleys

Timing belt pulleys

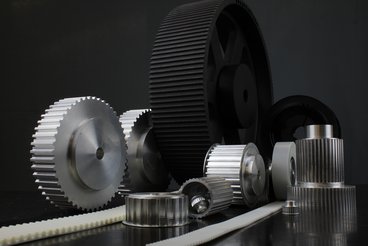

Timing belt pulleys are precision components manufactured using milling tools for accurate pitch. This ensures that the teeth engage precisely and the pitch of the belt and pulley match exactly. The performance of a timing belt drive is strongly influenced by the quality of the associated pulley. We supply timing belt pulleys ex stock either pre-bored or with the taper clamping bush system.

Further information about our timing belt pulleys:

It is extremely important to match the pitch of the pulley and the belt in timing belt drives. Torques are positively transmitted. The teeth of the belts must fit into the tooth gaps of the corresponding profile pulley without friction. For difficult drive problems and serial applications, we recommend that you contact us for advice!

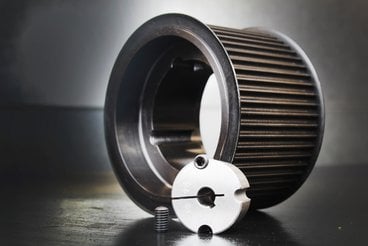

Depending on the operating conditions and gear load, timing belt pulleys can be made of grey cast iron, steel or aluminium alloys. The version depends on the manufacturer and may vary. Smaller timing belt pulleys are supplied from the factory with flanged pulleys. Flanged pulleys prevent the timing belts from slipping off. In a timing belt drive at least one of two timing belt pulleys need two flanged wheels. The self tracking HOT Helical Offset Tooth design of Conti® SilentSync eliminates the need for pulley flanges. We supply timing belt pulleys either pre-bored or with a clamping bush system such as Taper-Lock®. This taper system is used more and more frequently because there is no need to bore and ream a groove directly into the pulley.

Advantages of timing belt drives:

- low-noise

- high power transmission due to the positive gearing

- high rotational speeds

- small installation dimensions

- tight wrap angles

A great deal of research was required to achieve the variety of timing or toothed belt drives that exist today. The stringent requirements of a wide range of drive systems have be taken into consideration. Ever greater power levels have to be transmitted as quietly as possible. Spatial conditions are to some extent very narrow - meanwhile there is a belt for almost every requirement and of course the corresponding pulley profile.

Standard timing belt pulleys

partly with or without flanged pulleys

- profile MXL 025 - 0,080" (2,032 mm)

- profile XL 037 - 1/5" (5,08 mm)

- profile L 050 | 075 | 100 - 3/8"(9,525 mm)

- profile H 100 | 150 | 200 | 300 - 1/2" (12,7 mm)

All technical files to be downloaded have been checked with the utmost diligence. Nevertheless, we cannot guarantee the accuracy and conformity to our stock products.

HTD® - standard timing belt pulleys

partly with or without flanged pulleys

- profile 3M - for belt width 9 mm | 15 mm

- profile 5M - for belt width 9 mm | 15 mm | 25 mm

- profile 8M - for belt width 20 mm | 30 mm | 50 mm | 85 mm

All technical files to be downloaded have been checked with the utmost diligence. Nevertheless, we cannot guarantee the accuracy and conformity to our stock products.

Standard timing belt pulleys (aluminium) – metric pitch

- profile T2.5 (pitch 2,5 mm) for belt width 6 mm

- profile T5 (pitch 5 mm) for belt width 10 mm | 16 mm | 25 mm

- profile T10 (pitch 10 mm) for belt width 16 mm | 25 mm | 32 mm | 50 mm

- profile AT3 (pitch 3 mm) for belt width 10 mm | 16 mm

- profile AT5 (pitch 5 mm) for belt width 10 mm | 16 mm | 25 mm

- profile AT10 (pitch 10 mm) for belt width 16 mm | 25 mm | 32 mm | 50 mm

All technical files to be downloaded have been checked with the utmost diligence. Nevertheless, we cannot guarantee the accuracy and conformity to our stock products.

Taper system timing belt pulleys

partly with or without flanged pulleys

- profile L 050 | 075 | 100 - 3/8" (9,525 mm)

- profile L 100 - 1/2" (12,7 mm)

- profile H 150 | 200 | 300 - 1/2" (12,7 mm)

All technical files to be downloaded have been checked with the utmost diligence. Nevertheless, we cannot guarantee the accuracy and conformity to our stock products.

HTD® - taper system timing belt pulleys

partly with or without flanged pulleys

- profile 5M - for belt width 15 mm

- profile 8M - for belt width 20 mm | 30 mm | 50 mm | 85 mm

- profile 14M - for belt width 40 mm | 55 mm | 85 mm | 115 mm | 170 mm

All technical files to be downloaded have been checked with the utmost diligence. Nevertheless, we cannot guarantee the accuracy and conformity to our stock products.

SYNCHROCHAIN®CTD - standard and taper system timing belt pulleys

for timing belts SYNCHROCHAIN®CTD or POLYCHAIN®GT

- profile PCGT/CTD 8M - for belt width 12 mm | 21 mm | 36 mm | 62 mm

- profile PCGT/CTD 14M - for belt width 37 mm | 68 mm

All technical files to be downloaded have been checked with the utmost diligence. Nevertheless, we cannot guarantee the accuracy and conformity to our stock products.