Elastic couplings

Elastic couplings

Couplings are machine elements that transmit torques and rotational speeds between two shafts. The connection between these shafts can be rigid, separable or elastic. From stock we sell elastic couplings, matching spacers, bolts, buffers, sleeves and clamping bushes Taper system. On request, we can also mechanically rework the couplings in-house.

Further information about our elastic couplings:

In mechanical drive systems, couplings allow reliable power transmission between two shafts that may even be slightly offset. Impacts from rotational speeds and torques as well as sound can be absorbed. We supply a wide range of couplings in various sizes, hardnesses, designs and materials. All our couplings are elastic.

Elastic tyre couplings FFX

Select a product group:

- type 40 – type 160

By combining different types of flange steel, the highly elastic FFX tyre couplingis suitable for many applications. Because of the special tyre design, this coupling can accommodate extremely large displacements with low restoring forces in each direction. The tyre can be radially mounted and disassembled as standard using a factory-made separating joint. It is made of natural rubber with a textile insert. Suitable for ambient temperatures between - 50 °C and + 50 °C. Please order any required clamping bushings separately.

- standard coupling for finish bore

- version for Taper clamping bushings

- mixed version standard / Taper

- components can be combined with each other as required

Elastic pin couplings Orpex®

Select a product group:

(similar to Rupex®)

- type 105 – type 285 (bigger sizes on demand)

The buffers and elastic elements of the Orpex® couplings, which are spherical and moveable in the mounting holes, allow for compensation of shaft misalignment in angular, radial or axial direction. The couplingscan be used for both directions of rotation and are suitable for reversing. The couplinghalves of our series WN 105 to WN 360 pin couplings are made of grey cast iron.

Elastic couplings HRC

Select a product group:

- Taper system with I- or A-flange, type 7 – type 28

- standard hub, type 7 – type 18

These jaw couplings are quickly and easily assembled or disassembled using a hex wrench. They are made of grey cast iron and are available with I-flange or A-flange. The elastic intermediate element, the cam ring or coupling star greatly reduces shock loads. It dampens torsional vibrations as well as noise. The deformability in the axial direction is free, so that no damaging axial force can act on the machine bearings with changing torque. Replacing the star is made possible by a simple axial shift of the coupling halves, in most cases without removal of the connected machines.

Please order the appropriate clamping bushes separately.

Elastic cam couplings NPX

Select a product group:

(identical N-Eupex®)

- construction A, tree-part type 110 – type 250 (part 1, 2, 3)

- construction B, two-part type 58 – type 250 (part 1, 4)

The NPX coupling is a cam coupling with a temperature resistance of - 20 °C to + 80 °C. The elastic elements have a hardness of NBR 80° Shore A. Due to the fixed position of these cams, the deformability in the axial direction is free. Even when torque is changing, no damaging axial forces can act on the machine bearings (up to the breaking moment of the cast iron transfer cams). For maintenance purposes, the elastic elements can also be re-ordered as sets.

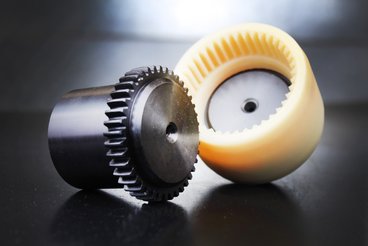

Curved-tooth couplings

Select a product group:

with polyamide sleeve

- type 14 – type 65

The curved-tooth coupling consists of two symmetrical hubs made of steel as well as an injection-moulded bushing made of a semi-crystalline technopolymer. The operation mode of the curved-tooth coupling prevents strain on the shaft in case of radial or angular misalignment. The combination of steel and polyamide makes the coupling maintenance-free and resistant to all types of hydraulic fluids and lubricants. Suitable for ambient temperatures between - 20 °C and + 120 °C.

Torsionally rigid self-aligning couplings / Mini couplings

Select a product group:

- MWK type 18 – type 80

The mini coupling is a backlash-free, torsionally rigid, flexible and, above all, maintenance-free coupling, made from one piece. It is suitable for propulsion systems which control and regulate highly dynamic processes in small installation spaces (medical technology, robots, transfer lines, etc.). Due to the mounting possibilities on shafts using clamping hubs, the mini coupling is very easy to install. It is completely suitable for use at temperatures from - 55 °C to + 150 °C (higher temperatures are possible following prior technical clarification).

Elastic couplings RPX/Habix®

Select a product group:

(similiar to Trasco®, Rotex®, Spidex® und Bipex®)

- HWT type 28 – type 75 Taper version GG25

- HWT type 38 – type 65 with flange GG25

- HWN type 19 – type 90 standard version GG25

- HWN type 19 – type 48 standard version aluminium

- intermediate rings (stars) yellow or red: available separately

The RPX coupling is a jaw coupling with elastic elements (intermediate ring or coupling star). Angular, radial, and axial motion between the two coupling halves is balanced. Torque transmission takes place as an interlocking. The standard intermediate ring has a hardness of 92 Shore A. However, the red, harder intermediate ring of 98 Shore A is available for purchase along with the coupling as well.

Please order clamping bushings separately.

Elastic couplings RPX/Habix®Plus (backlash-free)

Select a product group:

- HPN type 19 – type 65

- HPK type 19 – type 65

- intermediate rings (stars) 98° Sh A / 64° Sh D type 19 – 65

RPX / Habix®plus couplings consist of two coupling hubs with concave drive claws, which have a high degree of concentricity and a high-precision star, made of extremely wear-resistant and temperature-resistant plastic. This coupling transmits the torque backlash-free and reduces vibrations. It decisively determines the features of the entire coupling or of the complete drive train. The star permits a continuous load of up to + 100 °C, while use at low temperatures is permissible at - 30 °C.

Elastic couplings Hadeflex®X

Select a product group:

- TX type 28 – type 110

- XW type 32 – type 100

The Hadeflex®X coupling is a fail-safe, torsional flexible jaw coupling made of grey cast iron. A cam ring or coupling star (the elastic intermediate element) compensates for axial, radial and angular shaft misalignments. The hardness of the star determines the torque to transmit and ensures damping and torsional rigidity.

- temperature resistance of - 20 °C to + 80 °C

- vibration damping

- simple installation

- compact drive solutions

We supply two different versions of the Hadeflex®X coupling. The TX version is prepared for the installation of Taper clamping bushes. TheTaper system offers a simple and flexible kind of the shaft-hub connection. Thanks to the international standard sizes of the Taper bushes, you change the bore diameters quickly and easily. The XW version is by default manufactured for cylindrical finish bores with a grove.

You may use the Hadeflex®X coupling in all areas of general mechanical and plant engineering, e.g. pumps and compressors, conveyor systems, gearboxes, etc.